Week 8 of the Castle was started with a discussion of the design that we could put forward to make a 1:1 iteration of our ideas in cardboard form. This discussion highlighted the fact that we spent a lot of time in diplomatic, circuitous talks with everybody not wanting to put forward any particular idea too strongly in case someone else thought that they were being bossy. It might in fact have made some parts of the design process easier if we did have a bossy so-and-so who wanted things to be done a certain way, because we were mainly left with a group of people worried to put their views on the table in case it was actually decided on. I think that that is what happened at the end of this particular discussion, where someone suggested that we should put forward the paper project with the mezzanine from the week before and suddenly the consensus was arrived at and the vague suggestion was taken for a democratic decision! But, once the decision was made all our forces were mobilised into making the 600 x 1200mm panels and hot gluing them together to make 3.6 x 3.6m walls for the design. Bek, Gabby, Hannah and a few others worked on the parameters for the floor plan and height, which were decided on to allow enough headroom for someone sitting up in bed on a mezzanine above a shower and toilet cubicle downstairs. The putting together of the panels on the floor meant that when we actually had them ready, the picking them up and putting them next to each other meant that everybody had a momentous revelation that 3.6 metres was really, REALLY tall! No one really thought about it too much when the height was decided on, but in person and actually looking up at and standing next to a 3.6m wall was very interesting for our design, and probably extremely informative for all our design processes!

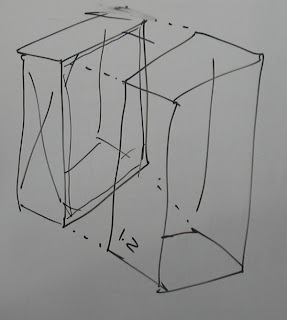

Fairly quickly it was decided that the enormous monstrosity that had been created needed to be cut down somewhat, so the height of the model was lowered to 3m high and we put some cardboard and polycarbonate plastic on the top to try and gauge what it felt like to be inside. It was very interesting being in and around the model, particularly because of the way that we had placed it, it was facing the afternoon sun, which I think made people think that the space we created was very adequate for size because it was a small, but light and airy space, which would have been small, dark and imposing perhaps if it had been facing the other way. This particular revelation of size and shape was the impetus for us deciding on a direction for the Castle, and it wasn’t particularly the design we had started the model with, with the mezzanine level above and things (but which we liked and wanted to continue later on), but how we would design a test rig and what the test rig would test. After lunch we thrashed this matter out. Again, long-winding and circuitous discussion, but pretty important. So we thought that the test rig should test dimensions. One model at 1:1 was all very well, but we needed to be able to test different heights to know what functions we would actually want in what size. It would also have to test lengths as well, whether we wanted long and thin or short and squat. The only thing that was relatively decided on was the width because the trailer-able size for transportable items on Tasmanian roads is 2.4m before it becomes over size and needs all the bells and whistles. In discussion the idea was put forward for a set of frames like a concertina that held the structure up, perhaps a series of portal frames. Another jumped in and suggested why don’t the portal frames be made of two U shapes that can slide up and down to test height. Another jumped in and suggested that if two frames were braced together to make two separate units then the space between them could be defined by how far apart they were pulled. From this set of decisions (and a whole lot of umms, ahhhs and pregnant pauses) we came up with the idea of the test rig.

We had another mid-week meeting to discuss the actual construction of the test rig and the two part portal idea we had proposed. This was to take into account the materials that we had available (135 x 35 x (round about) 4.5m lengths). Matt did some calculations and I proposed a bolting system (which in fact was very similar to one we had decided to use for our emergency shelter in first year) that would enable the 4.5m lengths to be cut and bolted together with some overlap at the corner joints and with a minimum overlap of the two U pieces of 600mm without wasting any timber. Overall, a very productive set of discussions that left those who attended (often not the full throng) with a clear indication of what the next step of serious exploration, with serious materials, would be.

No comments:

Post a Comment